研究成果

2025年10月現在

●論文成果抜粋

NEXTAで行われている研究について主要な成果論文の抜粋を示します。NEXTAでは金属材料に関する基礎・応用研究を、共同研究としてオックスフォード大学をはじめとする外部機関と積極的に行っています。

2025年

Maekawa, T.; Kohno, Y.; Yasuhara, A.; Morishita, S.; Inoue, T.; Ueda, Y.; Arakawa, K.; “Development of an image-forming system for the magnetic field-free electron microscope,” Ultramicroscopy, 276 (2025) 114181.https://doi.org/10.1016/j.ultramic.2025.114181

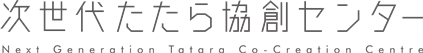

Karan, B.; Tan, Q.; Moheimani, K.; Shinjo, J.; Panwisawas, C.; Bhowmik, A.; Zhang, M.; “Achieving superior strength and corrosion resistance synergy in 316L stainless steel nanocomposites using ceramic nanoparticles by laser powder bed fusion approach,” Progress in Additive Manufacturing, (2025).https://doi.org/10.1007/s40964-025-01331-x

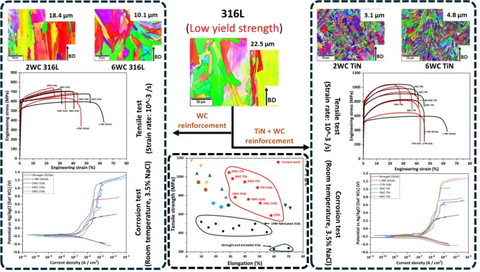

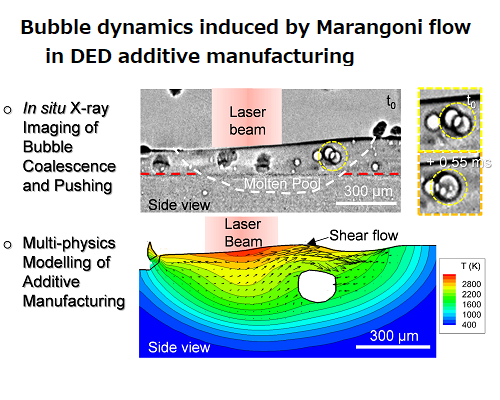

Zhang, K.; Bhagavath, S.; Marussi, S.; Rack, A.; Atwood, R.; Jones, M.A.; Leung, C.L.A.; Panwisawas, C.; Shinjo, J.; Lee, P.D.; “Pore-lean directed energy deposition additive manufacturing through laser power modulation,” Acta Materialia 301 (2025) 121515.https://doi.org/10.1016/j.actamat.2025.121515

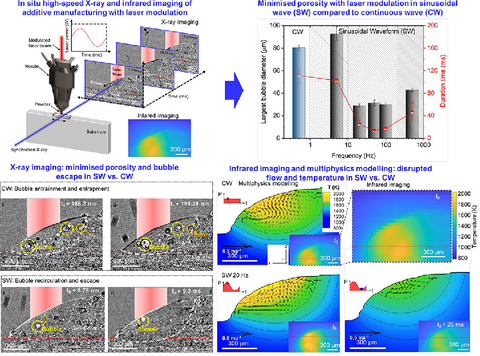

Dai, G.; Min, J.; Sun, Z.; Guo, Y.; Bhowmik, A.; Shinjo, J.; Lu, J.; Panwisawas, C.; “Tailoring microstructure in functionally graded NiTi alloys using in-situ alloying directed energy deposition,” Journal of Materials Processing Technology, 341 (2025) 118884.

https://doi.org/10.1016/j.jmatprotec.2025.118884

Wu, Y.; Tang, Y.T.; Barras, J.; Shinjo, J.; “Understanding Extreme High-speed Laser Material Deposition: Characterisation, Modelling and Bonding Mechanisms,” Surface & Coatings Technology, 511 (2025) 132218.

https://doi.org/10.1016/j.surfcoat.2025.132218

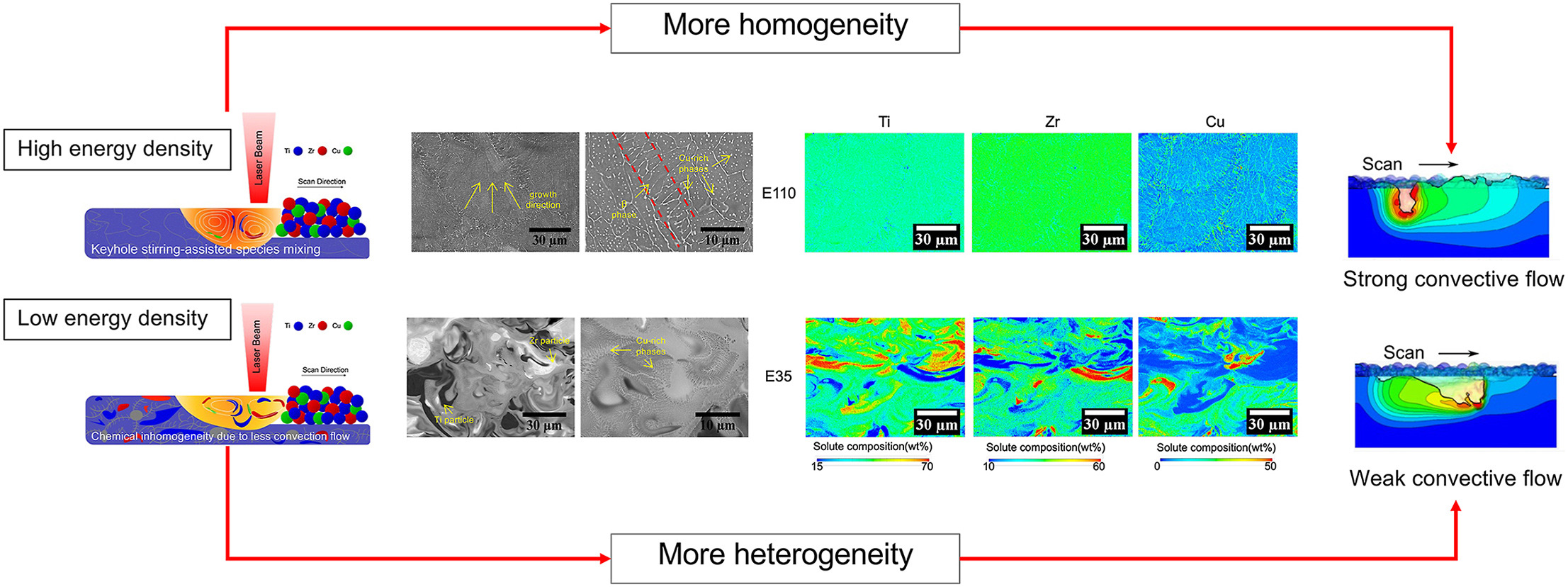

Wannapraphai, P.; Panwisawas, C.; Houghton, O.S.; Shinjo, J.; Wakabayashi, H.; Phetrattanarangsi, T.; Kuimalee, S.; Reed, R.C.; Greer, A.L.; Lohwongwatana, B.; Puncreobutr, C.; “Quantifying chemical homogeneity across the melt pool in laser powder-bed fusion of metallic glass matrix composites from blended elemental powders,” Journal of Materials Research and Technology, 35 (2025) 6397-6407.

https://doi.org/10.1016/j.jmrt.2025.02.204

Leung, C.L.A.; Gardy, J.; Isaacs, M.; Marathe, S.; Kłosowski, M.M.; Shinjo, J.; Panwisawas, C.; Lee, P.D.; “Unravel melt pool and bubble dynamics during laser powder bed fusion of polyamides using synchrotron X-ray imaging and process simulation,” Virtual and Physical Prototyping, 20 (2025) e2465905.

https://doi.org/10.1080/17452759.2025.2465905

Zhong, A.; Lapointe, C.; Goryaeva, A.M.; Arakawa, K.; Athènes, M.;Marinica, M.C.; "Unraveling temperature-induced vacancy clustering in tungsten: from direct microscopy to atomistic insights via data-driven Bayesian sampling," PRX Energy, 4 (2025) 013008.

http://doi.org/10.1103/PRXEnergy.4.013008

2024年

Kunioka, H.; Shiojiri, D.; Takahashi, S.; Hiratsuka, K.; Yamaguchi, M.; Hirayama, N.; Imai, Y.; Imai, M.; Iida, T.; “Investigation of group 13 elements as potential candidates for p-type dopants in the narrow-gap thermoelectric semiconductor α-SrSi2”, Journal of Materials Science, 59 (2024) 7840-7853.

https://doi.org/10.1007/s10853-024-09653-x

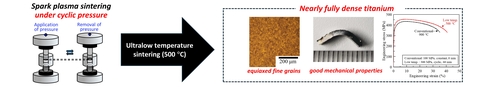

Manabe, N; Suzuki, AS; Ninagawa, M; Wakabayashi, H; Hirayama, N; Niinobe, K; Tang, YT; Utada, S; McCartney, DG; Reed, RC; Kitagawa, H: “Ultralow-Temperature Sintering of Titanium Powder by Spark Plasma Sintering under Cyclic Pressure,” Advanced Engineering Materials, 26 (2024) 2400965.

https://doi.org/10.1002/adem.202400965

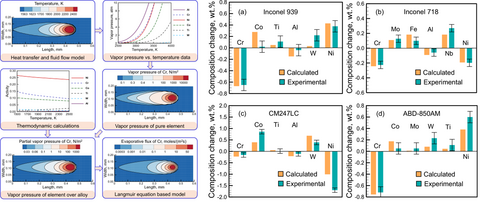

Mukherjee, T; Shinjo, J; DebRoy, T; Panwisawas, C; “Integrated modeling to control vaporization-induced composition change during additive manufacturing of nickel-based superalloys,” npj Computational Materials, 10 (2024) 230.

https://doi.org/10.1038/s41524-024-01418-z

Aliyu, AAA; Puncreobutr, C; Kuimalee, S; Phetrattanarangsi, T; Boonchuduang, T; Taweekitikul, P; Panwisawas, C; Shinjo, J; Lohwongwatana, B; “Laser-inherent porosity defects in additively manufactured Ti-6Al-4V implant: Formation, distribution, and effect on fatigue performance,” Journal of Materials Research and Technology, 30 (2024) 5121-5132.

https://doi.org/10.1016/j.jmrt.2024.04.225

Zhang, K; Chen, Y; Marussi, S; Fan, X; Fitzpatrick, M; Bhagavath, S; Majkut, M; Lukic, B; Jakata, K; Rack, A; Jones, MA; Shinjo, J; Panwisawas, C; Leung, CLA; Lee, PD; “Pore evolution mechanisms during directed energy deposition additive manufacturing,” Nature Communications, 15 (2024) 1715.

https://doi.org/10.1038/s41467-024-45913-9

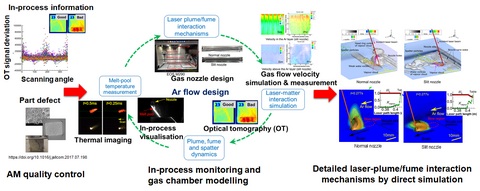

Shinjo, J; Kutsukake, A; Wakabayashi, H; Arakawa, K; Ogawara, A; Uchida, H; Panwisawas, C; Reed, RC; “In-process monitoring and direct simulation of Argon shielding gas and vapour dynamics to control laser-matter interaction in laser powder bed fusion additive manufacturing,” Additive Manufacturing, 80 (2024) 103953.

https://doi.org/10.1016/j.addma.2023.103953

2023年

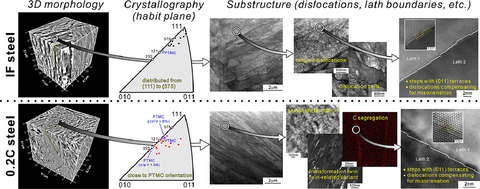

Shibata, A; Miyamoto, G; Morito, S; Nakamura, A; Moronaga, T; Kitano, H; Gutierrez-Urrutia, I; Hara, T; Tsuzaki, K; “Substructure and crystallography of lath martensite in as-quenched interstitial-free steel and low-carbon steel,” Acta Materialia, 246 (2023) 118675.

https://doi.org/10.1016/j.actamat.2023.118675

Dai, G; Sun, Z; Li, Y; Jain, J; Bhowmik, A; Shinjo, J; Lu, J; Panwisawas, C; “Grain refinement and columnar to equiaxed transition of Ti6Al4V during additive manufacturing via different laser oscillations,” International Journal of Machine Tools and Manufacture, 189 (2023) 104031.

https://doi.org/10.1016/j.ijmachtools.2023.104031

Shinjo, J; Kutsukake, A; Arote A; Tang, YT; McCartney, DG; Reed, RC; Panwisawas, C, “Physics-based thermal-chemical-fluid-microstructure modelling of in-situ alloying using additive manufacturing: Composition-microstructure control,” Additive Manufacturing, 64 (2023) 103428

https://doi.org/10.1016/j.addma.2023.103428

2022年

Tang, YT; Pham, AH; Morito, S; McCartney, DG; Reed, RC, “On the solid-state dendritic growth of M7C3 carbide at interfaces in an austenitic system,” Scripta Materialia, 213 (2022) 114585

https://doi.org/10.1016/j.scriptamat.2022.114585

Shiojiri, D; Iida, T; Kakio, H; Yamaguchi, M; Hirayama, N; Imai, Y, “Enhancement of thermoelectric performance of Mg2Si via co-doping Sb and C by simultaneous tuning of electronic and thermal transport properties,” Journal of Alloys and Compounds, 891 (2022) 161968

https://doi.org/10.1016/j.jallcom.2021.161968

Shinjo, J; Panwisawas, C, “Chemical species mixing during direct energy deposition of bimetallic systems using titanium and dissimilar refractory metals for repair and biomedical applications,” Additive Manufacturing, 51 (2022) 102654

https://doi.org/10.1016/j.addma.2022.102654

Hara, T; Habe, M; Nakanishi, H; Fujimura, T; Sasai, R; Moriyoshi, C; Kawaguchi, S; Ichikuni, N; Shimazu, S, “Specific lift-up behaviour of acetate-intercalated layered yttrium hydroxide interlayer in water: application for heterogeneous Bronsted base catalysts toward Knoevenagel reactions,” Catalysis Science & Technology, 12 (2022) 2061-2070

https://doi.org/10.1039/d1cy02328d

2021年

Shinjo, J; Panwisawas, C, “Digital materials design by thermal-fluid science for multi-metal additive manufacturing,” Acta Materialia, 210 (2021) 116825

https://doi.org/10.1016/j.actamat.2021.116825

Panwisawas, C; Gong, YL; Tang, YT; Reed, RC; Shinjo, J, “Additive manufacturability of superalloys: Process-induced porosity, cooling rate and metal vapour,” Additive Manufacturing, 47 (2021) 102339

https://doi.org/10.1016/j.addma.2021.102339

2020年

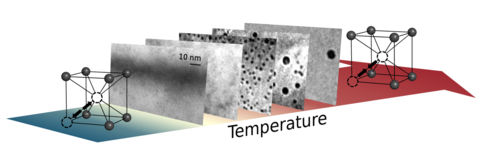

Arakawa, K; Marinica, MC; Fitzgerald, S; Proville, L; Duc, NM; Dudarev, SL; Ma, PW; Swinburne, TD; Goryaeva, AM; Yamada, T; Amino, T; Arai, S; Yamamoto, Y; Higuchi, K; Tanaka, N; Yasuda, H; Yasuda, T; Mori, H, “Quantum de-trapping and transport of heavy defects in tungsten,” Nature Materials, 19 (2020) 508-511

https://doi.org/10.1038/s41563-019-0584-0

Du, JP; Geng, WT; Arakawa, K; Li, J; Ogata, S, “Hydrogen-Enhanced Vacancy Diffusion in Metals,” Journal of Physical Chemistry Letters, 11 (2020) 7015-7020

https://doi.org/10.1021/acs.jpclett.0c01798

2018年

Suzuki, A; Kitagawa, H; Ido, S; Pham, AH; Morito, S; Etoh, T; Kikuchi, K, “Microstructure control of Bi0.4Sb1.6Te3 thermoelectric material by pulse-current sintering under cyclic uniaxial pressure,” Journal of Alloys and Compounds, 742 (2018) 240-247

https://doi.org/10.1016/j.jallcom.2018.01.269

●科研費(2018年以降実績)

・新城淳史,基盤研究(B),ISS実験研究成果の社会還元のための噴霧シミュレータ開発と噴霧物理解明,2018年4月1日~2020年3月31日

・新城淳史,基盤研究(B),新規開発した微粒化・遷臨界蒸発モデルによる航空エンジン燃焼器性能向上の解析,2020年4月1日~2023年3月31日

・荒河一渡,基盤研究(A),点欠陥を骨組みとする新しい同素変態―鉄鋼材料の新たな高強度化法の開拓,2020年4月1日~2024年3月31日

・荒河一渡,基盤研究(A),金属中の水素がもたらす欠陥の異常挙動の解明:水素脆化を支配する欠陥の学理構築,2025年4月1日~2029年3月31日

●受託研究(件数と総額)

2018年度 3件 16,681千円

2019年度 2件 1,616千円

2020年度 2件 4,869千円

2021年度 5件 12,677千円

2022年度 4件 18,470千円

●共同研究(件数と総額)

2018年度 6件 13,481千円

2019年度 7件 70,783千円

2020年度 6件 49,333千円

2021年度 10件 81,014千円

2022年度 5件 89,121千円