Research results

As of Oct, 2025

●Selected publications

Shown below are selected publications by NEXTA researchers during the Tatara Project since 2018. At NEXTA, both fundamental and applied research projects on metal materials are being conducted in cooperation with joint institutes such as the University of Oxford.

2025

Maekawa, T.; Kohno, Y.; Yasuhara, A.; Morishita, S.; Inoue, T.; Ueda, Y.; Arakawa, K.; “Development of an image-forming system for the magnetic field-free electron microscope,” Ultramicroscopy, 276 (2025) 114181.https://doi.org/10.1016/j.ultramic.2025.114181

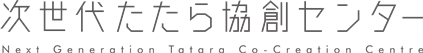

Karan, B.; Tan, Q.; Moheimani, K.; Shinjo, J.; Panwisawas, C.; Bhowmik, A.; Zhang, M.; “Achieving superior strength and corrosion resistance synergy in 316L stainless steel nanocomposites using ceramic nanoparticles by laser powder bed fusion approach,” Progress in Additive Manufacturing, (2025).https://doi.org/10.1007/s40964-025-01331-x

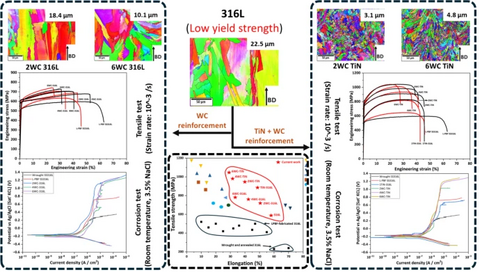

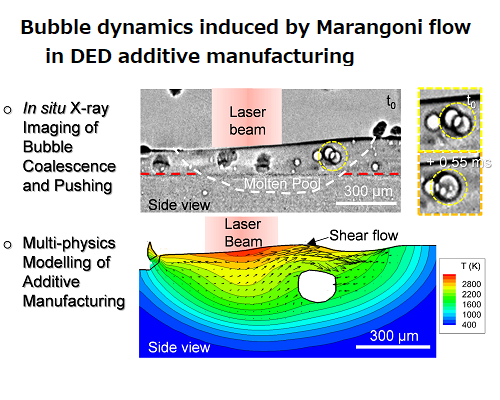

Zhang, K.; Bhagavath, S.; Marussi, S.; Rack, A.; Atwood, R.; Jones, M.A.; Leung, C.L.A.; Panwisawas, C.; Shinjo, J.; Lee, P.D.; “Pore-lean directed energy deposition additive manufacturing through laser power modulation,” Acta Materialia 301 (2025) 121515.https://doi.org/10.1016/j.actamat.2025.121515

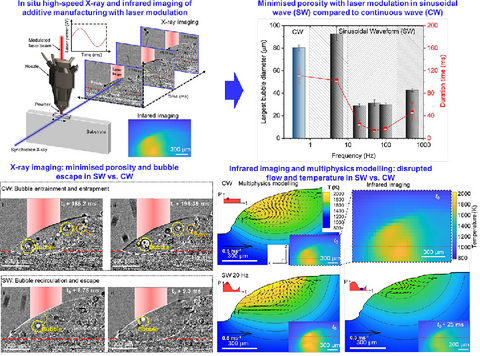

Dai, G.; Min, J.; Sun, Z.; Guo, Y.; Bhowmik, A.; Shinjo, J.; Lu, J.; Panwisawas, C.; “Tailoring microstructure in functionally graded NiTi alloys using in-situ alloying directed energy deposition,” Journal of Materials Processing Technology, 341 (2025) 118884.

https://doi.org/10.1016/j.jmatprotec.2025.118884

Wu, Y.; Tang, Y.T.; Barras, J.; Shinjo, J.; “Understanding Extreme High-speed Laser Material Deposition: Characterisation, Modelling and Bonding Mechanisms,” Surface & Coatings Technology, 511 (2025) 132218.

https://doi.org/10.1016/j.surfcoat.2025.132218

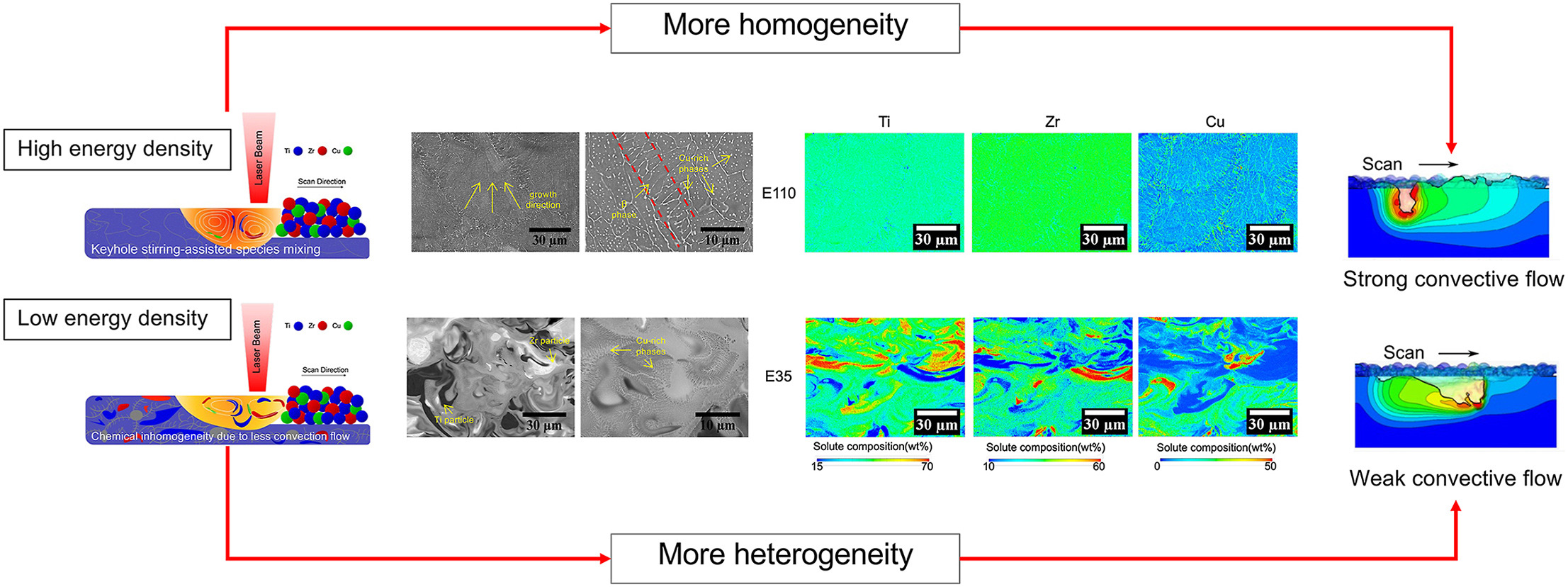

Wannapraphai, P.; Panwisawas, C.; Houghton, O.S.; Shinjo, J.; Wakabayashi, H.; Phetrattanarangsi, T.; Kuimalee, S.; Reed, R.C.; Greer, A.L.; Lohwongwatana, B.; Puncreobutr, C.; “Quantifying chemical homogeneity across the melt pool in laser powder-bed fusion of metallic glass matrix composites from blended elemental powders,” Journal of Materials Research and Technology, 35 (2025) 6397-6407.

https://doi.org/10.1016/j.jmrt.2025.02.204

Leung, C.L.A.; Gardy, J.; Isaacs, M.; Marathe, S.; Kłosowski, M.M.; Shinjo, J.; Panwisawas, C.; Lee, P.D.; “Unravel melt pool and bubble dynamics during laser powder bed fusion of polyamides using synchrotron X-ray imaging and process simulation,” Virtual and Physical Prototyping, 20 (2025) e2465905.

https://doi.org/10.1080/17452759.2025.2465905

Zhong, A.; Lapointe, C.; Goryaeva, A.M.; Arakawa, K.; Athènes, M.;Marinica, M.C.; "Unraveling temperature-induced vacancy clustering in tungsten: from direct microscopy to atomistic insights via data-driven Bayesian sampling," PRX Energy, 4 (2025) 013008.

http://doi.org/10.1103/PRXEnergy.4.013008

2024

Kunioka, H.; Shiojiri, D.; Takahashi, S.; Hiratsuka, K.; Yamaguchi, M.; Hirayama, N.; Imai, Y.; Imai, M.; Iida, T.; “Investigation of group 13 elements as potential candidates for p-type dopants in the narrow-gap thermoelectric semiconductor α-SrSi2”, Journal of Materials Science, 59 (2024) 7840-7853.

https://doi.org/10.1007/s10853-024-09653-x

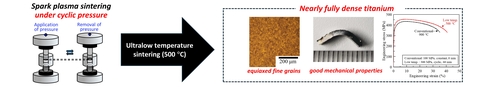

Manabe, N; Suzuki, AS; Ninagawa, M; Wakabayashi, H; Hirayama, N; Niinobe, K; Tang, YT; Utada, S; McCartney, DG; Reed, RC; Kitagawa, H: “Ultralow-Temperature Sintering of Titanium Powder by Spark Plasma Sintering under Cyclic Pressure,” Advanced Engineering Materials, 26 (2024) 2400965.

https://doi.org/10.1002/adem.202400965

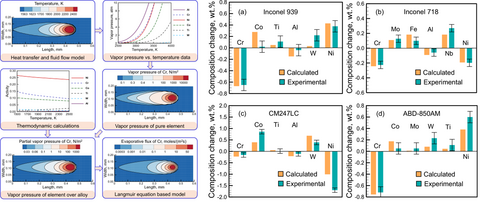

Mukherjee, T; Shinjo, J; DebRoy, T; Panwisawas, C; “Integrated modeling to control vaporization-induced composition change during additive manufacturing of nickel-based superalloys,” npj Computational Materials, 10 (2024) 230.

https://doi.org/10.1038/s41524-024-01418-z

Aliyu, AAA; Puncreobutr, C; Kuimalee, S; Phetrattanarangsi, T; Boonchuduang, T; Taweekitikul, P; Panwisawas, C; Shinjo, J; Lohwongwatana, B; “Laser-inherent porosity defects in additively manufactured Ti-6Al-4V implant: Formation, distribution, and effect on fatigue performance,” Journal of Materials Research and Technology, 30 (2024) 5121-5132.

https://doi.org/10.1016/j.jmrt.2024.04.225

Zhang, K; Chen, Y; Marussi, S; Fan, X; Fitzpatrick, M; Bhagavath, S; Majkut, M; Lukic, B; Jakata, K; Rack, A; Jones, MA; Shinjo, J; Panwisawas, C; Leung, CLA; Lee, PD; “Pore evolution mechanisms during directed energy deposition additive manufacturing,” Nature Communications, 15 (2024) 1715.

https://doi.org/10.1038/s41467-024-45913-9

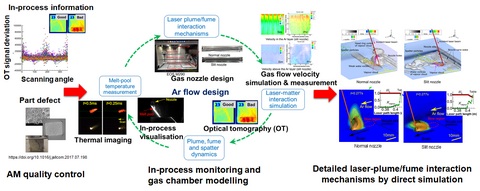

Shinjo, J; Kutsukake, A; Wakabayashi, H; Arakawa, K; Ogawara, A; Uchida, H; Panwisawas, C; Reed, RC; “In-process monitoring and direct simulation of Argon shielding gas and vapour dynamics to control laser-matter interaction in laser powder bed fusion additive manufacturing,” Additive Manufacturing, 80 (2024) 103953.

https://doi.org/10.1016/j.addma.2023.103953

2023

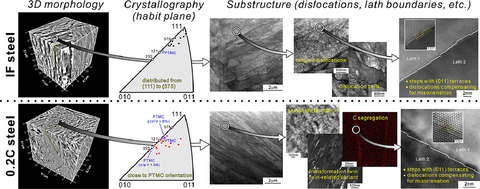

Shibata, A; Miyamoto, G; Morito, S; Nakamura, A; Moronaga, T; Kitano, H; Gutierrez-Urrutia, I; Hara, T; Tsuzaki, K; “Substructure and crystallography of lath martensite in as-quenched interstitial-free steel and low-carbon steel,” Acta Materialia, 246 (2023) 118675.

https://doi.org/10.1016/j.actamat.2023.118675

Dai, G; Sun, Z; Li, Y; Jain, J; Bhowmik, A; Shinjo, J; Lu, J; Panwisawas, C; “Grain refinement and columnar to equiaxed transition of Ti6Al4V during additive manufacturing via different laser oscillations,” International Journal of Machine Tools and Manufacture, 189 (2023) 104031.

https://doi.org/10.1016/j.ijmachtools.2023.104031

Shinjo, J; Kutsukake, A; Arote A; Tang, YT; McCartney, DG; Reed, RC; Panwisawas, C, “Physics-based thermal-chemical-fluid-microstructure modelling of in-situ alloying using additive manufacturing: Composition-microstructure control,” Additive Manufacturing, 64 (2023) 103428

https://doi.org/10.1016/j.addma.2023.103428

2022

Tang, YT; Pham, AH; Morito, S; McCartney, DG; Reed, RC, “On the solid-state dendritic growth of M7C3 carbide at interfaces in an austenitic system,” Scripta Materialia, 213 (2022) 114585

https://doi.org/10.1016/j.scriptamat.2022.114585

Shiojiri, D; Iida, T; Kakio, H; Yamaguchi, M; Hirayama, N; Imai, Y, “Enhancement of thermoelectric performance of Mg2Si via co-doping Sb and C by simultaneous tuning of electronic and thermal transport properties,” Journal of Alloys and Compounds, 891 (2022) 161968

https://doi.org/10.1016/j.jallcom.2021.161968

Shinjo, J; Panwisawas, C, “Chemical species mixing during direct energy deposition of bimetallic systems using titanium and dissimilar refractory metals for repair and biomedical applications,” Additive Manufacturing, 51 (2022) 102654

https://doi.org/10.1016/j.addma.2022.102654

Hara, T; Habe, M; Nakanishi, H; Fujimura, T; Sasai, R; Moriyoshi, C; Kawaguchi, S; Ichikuni, N; Shimazu, S, “Specific lift-up behaviour of acetate-intercalated layered yttrium hydroxide interlayer in water: application for heterogeneous Bronsted base catalysts toward Knoevenagel reactions,” Catalysis Science & Technology, 12 (2022) 2061-2070

https://doi.org/10.1039/d1cy02328d

2021

Shinjo, J; Panwisawas, C, “Digital materials design by thermal-fluid science for multi-metal additive manufacturing,” Acta Materialia, 210 (2021) 116825

https://doi.org/10.1016/j.actamat.2021.116825

Panwisawas, C; Gong, YL; Tang, YT; Reed, RC; Shinjo, J, “Additive manufacturability of superalloys: Process-induced porosity, cooling rate and metal vapour,” Additive Manufacturing, 47 (2021) 102339

https://doi.org/10.1016/j.addma.2021.102339

2020

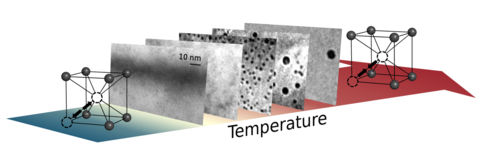

Arakawa, K; Marinica, MC; Fitzgerald, S; Proville, L; Duc, NM; Dudarev, SL; Ma, PW; Swinburne, TD; Goryaeva, AM; Yamada, T; Amino, T; Arai, S; Yamamoto, Y; Higuchi, K; Tanaka, N; Yasuda, H; Yasuda, T; Mori, H, “Quantum de-trapping and transport of heavy defects in tungsten,” Nature Materials, 19 (2020) 508-511

https://doi.org/10.1038/s41563-019-0584-0

Du, JP; Geng, WT; Arakawa, K; Li, J; Ogata, S, “Hydrogen-Enhanced Vacancy Diffusion in Metals,” Journal of Physical Chemistry Letters, 11 (2020) 7015-7020

https://doi.org/10.1021/acs.jpclett.0c01798

2018

Suzuki, A; Kitagawa, H; Ido, S; Pham, AH; Morito, S; Etoh, T; Kikuchi, K, “Microstructure control of Bi0.4Sb1.6Te3 thermoelectric material by pulse-current sintering under cyclic uniaxial pressure,” Journal of Alloys and Compounds, 742 (2018) 240-247

https://doi.org/10.1016/j.jallcom.2018.01.269

●Grant-in-Aid for Scientific Research ( since 2018 )

- J. Shinjo, Grant-in-Aid for Scientific Research(B),Development of a novel spray simulator and elucidation of spray formation mechanisms based on ISS atomization experiments,April 2018 to March 2020

- J. Shinjo, Grant-in-Aid for Scientific Research (B), Numercal simulation of aero-engine performance improvement by the newly-developed atomization and transcritical evaporation model, April 2020 to March 2023

●Consignment research

2018 3 subjects 16,681 k yen

2019 2 subjects 1,616 k yen

2020 2 subjects 4,869 k yen

2021 5 subjects 12,677 k yen

2022 4 subjects 18,470 k yen

●Joint research

2018 6 subjects 13,481 k yen

2019 7 subjects 70,783 k yen

2020 6 subjects 49,333 k yen

2021 10 subjects 81,014 k yen

2022 5 subjects 89,121 k yen